Table of Contents

- Introduction

- Applications Across Industries

- Advancements in Temperature Chamber Technology

- Challenges and Considerations

- Conclusion

Introduction

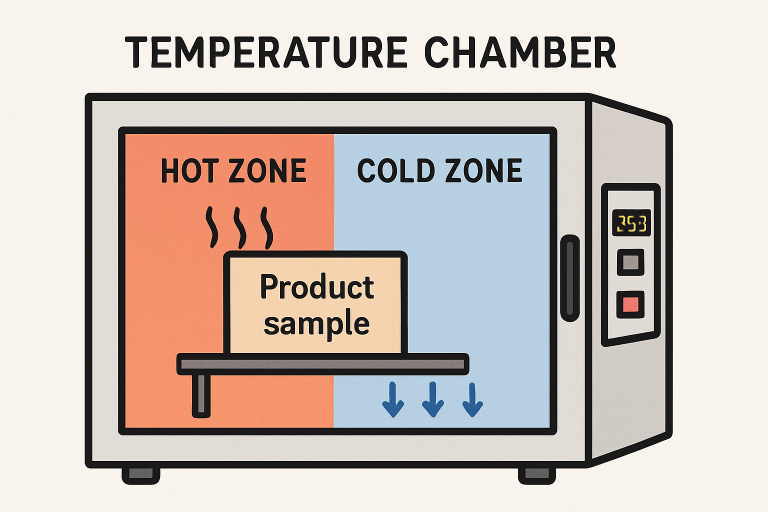

In a rapidly evolving product development landscape, temperature chambers play a crucial role in enabling innovation. These advanced testing environments empower research and development (R&D) teams to replicate a wide range of climate conditions with extraordinary precision. By exposing products and materials to tightly regulated extremes—ranging from subzero cold to intense heat—temperature chambers enable engineers and scientists to collect meaningful data on how various components respond under stress. This capability not only allows manufacturers to identify design limitations but also helps validate crucial safety features that could make the difference between product success and catastrophic failure. Ultimately, temperature chambers give organizations the means to accelerate time-to-market for innovative products, all without compromising on quality or thoroughness in evaluation. Their value during concept prototyping, iterative design, and quality assurance is now regarded as indispensable within the world’s most competitive and quality-focused industries.

From microchips to pharmaceuticals, industries rely on temperature chambers to analyze how their products perform under anticipated and unexpected stressors. For instance, manufacturers can assess the long-term durability and stability of materials or electronics by repeatedly exposing them to fluctuating, sometimes volatile, climate conditions. This rigorous, data-driven approach to validation is foundational to modern R&D workflows. It ensures that new technologies, medicines, or components will withstand unpredictable and routine challenges once they reach the end user. As regulatory agencies and quality standards become more stringent, the pressure to simulate real-world phenomena as closely as possible continues to rise, making the temperature chamber a core piece of laboratory and production infrastructure.

Applications Across Industries

Temperature chambers are indispensable to an array of industries, each with unique requirements but a common objective: producing resilient, high-quality products. In the fast-paced electronics sector, these chambers test semiconductors and circuit boards under extreme temperature cycles to guarantee device reliability and longevity. Many electronic devices, from smartphones to medical equipment, must operate flawlessly within a specified range of thermal conditions, and detailed testing replicates years’ worth of wear in mere weeks. Pharmaceutical manufacturers, meanwhile, rely on temperature chambers for stability testing, ensuring that medications and vaccines retain their efficacy throughout their shelf life and under various storage or transit scenarios. Regulatory agencies often require this level of climate-controlled validation to approve products for market, making the proper use of temperature chambers an industry-wide necessity. According to Archive Market Research, the Temperature & Humidity Test Chamber Market Report provides an in-depth overview of the capabilities and applications of these systems.

The automotive industry similarly depends on temperature chambers, subjecting vehicle components such as engines, batteries, interior plastics, and safety systems to simulated extremes of heat, cold, and humidity. Such rigorous assessment ensures that vehicles remain safe and comfortable for drivers worldwide, from deserts to polar regions. Likewise, the aerospace sector leverages these chambers to qualify materials and systems before they embark on high-stakes missions into space, where atmospheric conditions can be harsh and unpredictable. Reliable performance can mean the difference between mission success and failure, underscoring the chambers’ vital contribution. The versatility of temperature chambers across diverse sectors highlights their critical importance in preventing costly product failures, reducing the risk of recalls, ensuring regulatory compliance, and protecting valuable brand reputations. For many organizations, this proactive approach to development and testing ultimately translates into lower long-term costs, increased product longevity, and enhanced customer trust and satisfaction.

Advancements in Temperature Chamber Technology

Recent years have seen significant innovation in temperature chamber technology, allowing organizations to extract more value and efficiency from each test cycle. Integration with IoT solutions now enables R&D teams to monitor, manage, and record tests remotely, shepherding vast amounts of real-time data straight to researchers’ tablets or smartphones, regardless of their location. With the addition of wireless sensors, digital twins, and advanced analytics, test parameters can be dynamically adjusted and deviations flagged instantly, reducing test errors and improving reproducibility. Automation and smart controls further streamline test procedures, minimize human error, and boost throughput, enabling the simultaneous execution of multiple complex test protocols—vital for keeping pace in industries where development timelines are shrinking. According to Investopedia, research and development (R&D) refers to the systematic activities organizations undertake to innovate, improve, or develop new products and services, making advanced testing technologies like temperature chambers a core part of modern R&D efforts.

In parallel, engineers have made strides in building chambers that are not only more powerful but also more energy-efficient. Advances such as improved insulation materials, environmentally friendly refrigerants, and variable-speed compressors contribute to reduced operational costs and a smaller carbon footprint. Many manufacturers now prioritize modular, scalable systems that adapt to the evolving needs of R&D labs, allowing smaller businesses to benefit from top-tier chamber performance without overspending. Collectively, these advances not only maximize the value of each test but also align with global movements for environmental responsibility and sustainable development. The move toward “greener” temperature chambers demonstrates a forward-thinking approach that balances precision engineering with environmental stewardship.

Challenges and Considerations

Despite their notable benefits, temperature chambers present several considerations and challenges for organizations aiming to integrate them into their R&D processes. The initial investment for advanced models—particularly those offering multi-functionality, automation, or a large testing capacity—can be significant. For smaller businesses and startups, capital costs may present a barrier. Furthermore, running these chambers, especially older or legacy models, may consume substantial energy, impacting not only operational budgets but also organizations’ sustainability efforts. The increasing focus on eco-friendly operations and stricter government regulations around energy usage make these considerations all the more pressing.

Nevertheless, as industry demands grow, manufacturers have responded by designing modular systems with energy-saving features that offer scalability and require less upfront investment. Such systems can be expanded or upgraded as a business grows, allowing even smaller organizations to access advanced testing capabilities without the financial burden of a major initial purchase. Careful evaluation of a chamber’s specifications, efficiency ratings, and long-term support options is essential during procurement to ensure meaningful alignment with R&D objectives. Furthermore, aligning the chamber’s capabilities with the specific test protocol is vital to ensure accurate, meaningful, and reproducible results. Routine maintenance and proper calibration also play critical roles in maximizing the laboratory’s return on investment and avoiding erroneous test outcomes. By addressing these considerations early, organizations can more readily harness the full benefits of this technology.

Conclusion

Temperature chambers have become foundational to innovation, reliability, and regulatory compliance in modern product development. Their ability to faithfully replicate challenging, real-world conditions enables R&D teams to discover potential weaknesses and correct them before products reach consumers, ultimately safeguarding public trust and minimizing unforeseen liabilities. From the lab bench to large-scale industrial applications, temperature chambers remain a pillar of quality assurance, providing stakeholders with confidence that products will perform as promised. As chamber technology continues to advance and the demands for precision and reliability rise alongside consumer and regulatory expectations, temperature chambers will maintain their vital role across all sectors—fueling the creation of next-generation solutions, protecting brand reputations, and shaping the future trajectory of research and development worldwide.

“In a world of instant takes and AI-generated noise, John Authers writes like a human. His words carry weight—not just from knowledge, but from care. Readers don’t come to him for headlines; they come for meaning. He doesn’t just explain what happened—he helps you understand why it matters. That’s what sets him apart.”